DIY How To Make Paper

To continue to write after a SHTF event will require three things, a writing instrument, ink, which we have already covered, and the other component is something to write on. Clay tablets were the first semi modern form of paper, but clay isn't very efficient. Let's try to jump straight to paper and bypass all the bulky, slow substrates that were used in ancient times.

Here we will cover an ancient Chinese method of making paper. So let's get started.

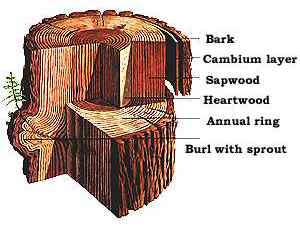

The first step in the DIY paper making process is to find small trees or saplings and strip off the bark. Strip the bark with the aid of a knife or ax. It does not matter if the bark is in pieces or long strips. Both will work. However, it is impractical to use plants that do not yield good long strips of bark simply because the time involved with processing small bark chips by hand is just way too time consuming.

Note: Other types of plant fibers, such as cotton, flax, bamboo, and hemp can be used separately or mixed with the wood pulp. Experimenting can improve the process.

The next step to paper is to submerge the bark strips in water. You will have to let it soak for at least a week.

After the bark is done soaking, place the bark strips in a bowl and again cover with water. Except this time and some wood ash to the bowl. This will change the pH of the water to hasten the process. Now light a fire and heat the bowl of water and bark to a slow boil. You will need to keep the water boiling for 8 to 12 hours. So don't build too big of a fire where you will constantly be adding more water to keep the bark covered. A bigger fire does not speed up the process. The temperature of the water cannot be increased no matter how hot the fire gets. A bigger fire only boils off the water more quickly. Remember you want water that has been treated with some ash for this step.

Remove from heat and water then pound the strips into a mushy pulp. A couple of rocks work. A flat rock and a club works better. A homemade butter churn works best. Periodically you might need to help things along by tearing the pieces into even small pieces. The end result should look like a bunch of great spitball material.

Again put the pulp back in a bowl and add water and ash and bring to a boil. Boil for an additional 4 hours or so.

How you preceed from here will depend on what you have available. The preferred method is to make a rectangular form around a fine mesh screen. Suspend in a shallow pool of still water your the frame so that there is water covering the screen, but not the actual frame.

Place the pulp inside the frame and agitate the water so that the particles get evenly distributed in the water. Then, gently lift the frame out of the water and let the pulp dry. At first just let it sit and drip. Once it has partially dried to the point that it can be turned and tilted without the paper moving like a soup will you can place it near a fire to speed up the process. Don't overdo the heat, you only want to warm it not really get it hot.

Place the pulp inside the frame and agitate the water so that the particles get evenly distributed in the water. Then, gently lift the frame out of the water and let the pulp dry. At first just let it sit and drip. Once it has partially dried to the point that it can be turned and tilted without the paper moving like a soup will you can place it near a fire to speed up the process. Don't overdo the heat, you only want to warm it not really get it hot.

Once the drying is done you should have a nice large sheet of paper. You will have to experiment to know how much pulp it takes to fill the from. More pulp will make the paper thicker, but will yield less paper surface area.

If you do not have a fine mesh screen then you can place the pulp on a flat rock or most any flat surface and heat it from below to dry it out. Roll it with a rolling pin to get an even thickness. Experimentation will teach you how thin you can go successfully.

As the moisture evaporates you will notice a color change from dark to lighter. When the entire sheet is white you will be finished. Allow to cool and start writing that novel.